A Chain Conveyor utilized in warehouses is a specialized type of conveyor system designed to efficiently move materials or packages through various stages of the warehousing process.

Definition

A chain conveyor, also known as a chain-driven conveyor, is a mechanical device that employs a continuous chain to convey goods or materials along a predetermined path. It is commonly used in warehousing for transporting packages, containers, or other items between different storage or processing areas.

Key Components

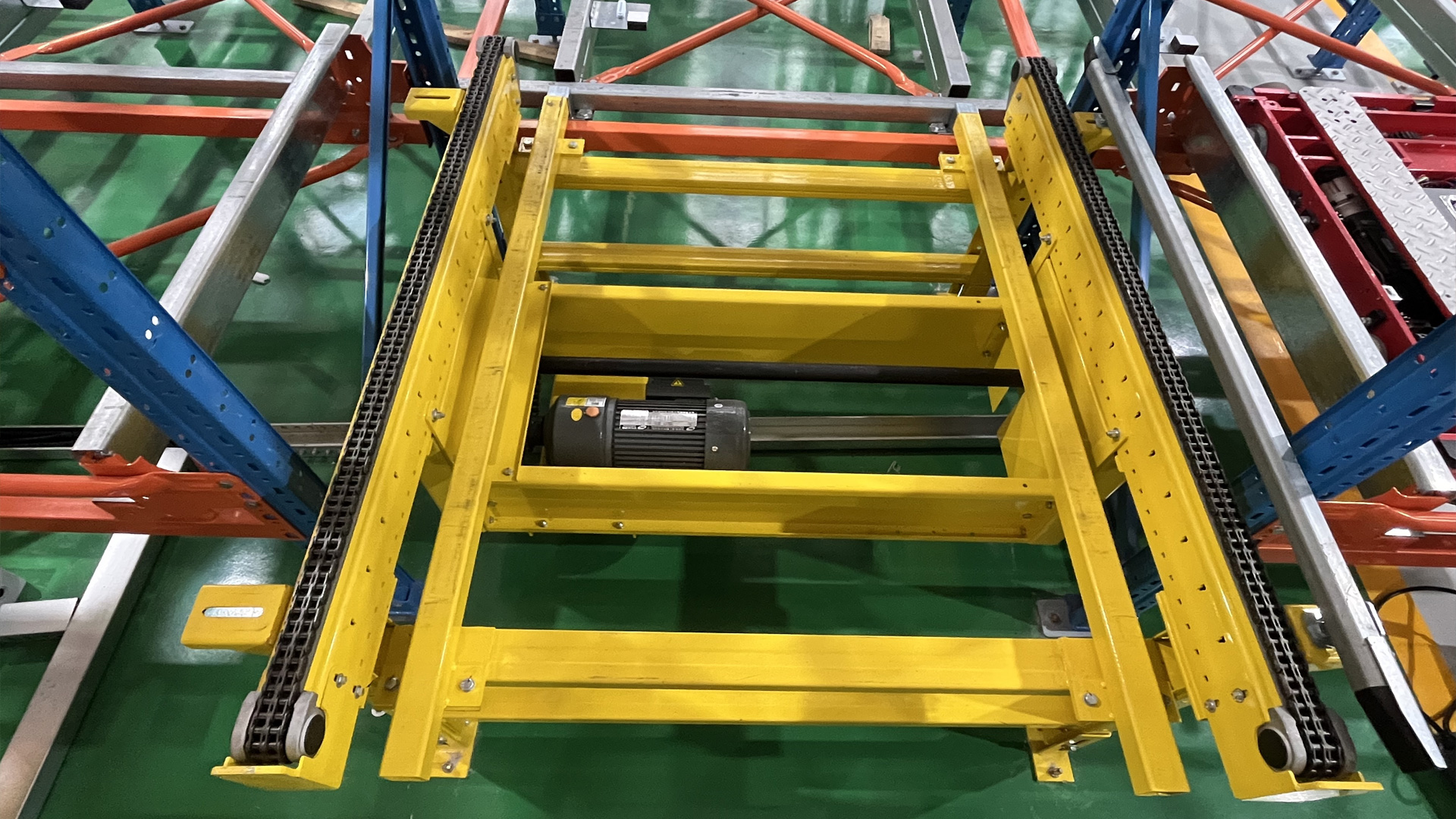

- Chain Assembly: The core of the chain conveyor, composed of links and roller pins connecting the links together, extending transverse of the conveyor path.

- Chain Protection Box: Encloses the chain to protect it from dust and debris, ensuring smooth operation and extending the lifespan of the conveyor.

- Rails: Provided within the chain protection box to support the roller pins and guide the movement of the chain.

- Connecting Elements: Extend out of the chain protection box through lateral slit recesses to support holders for the containers or packages being transported.

- Shielding Belt: Formed of a succession of laminae pivotally mounted on the roller pins, covering the slit recess to prevent dust and debris from entering the conveyor system.

Functionality

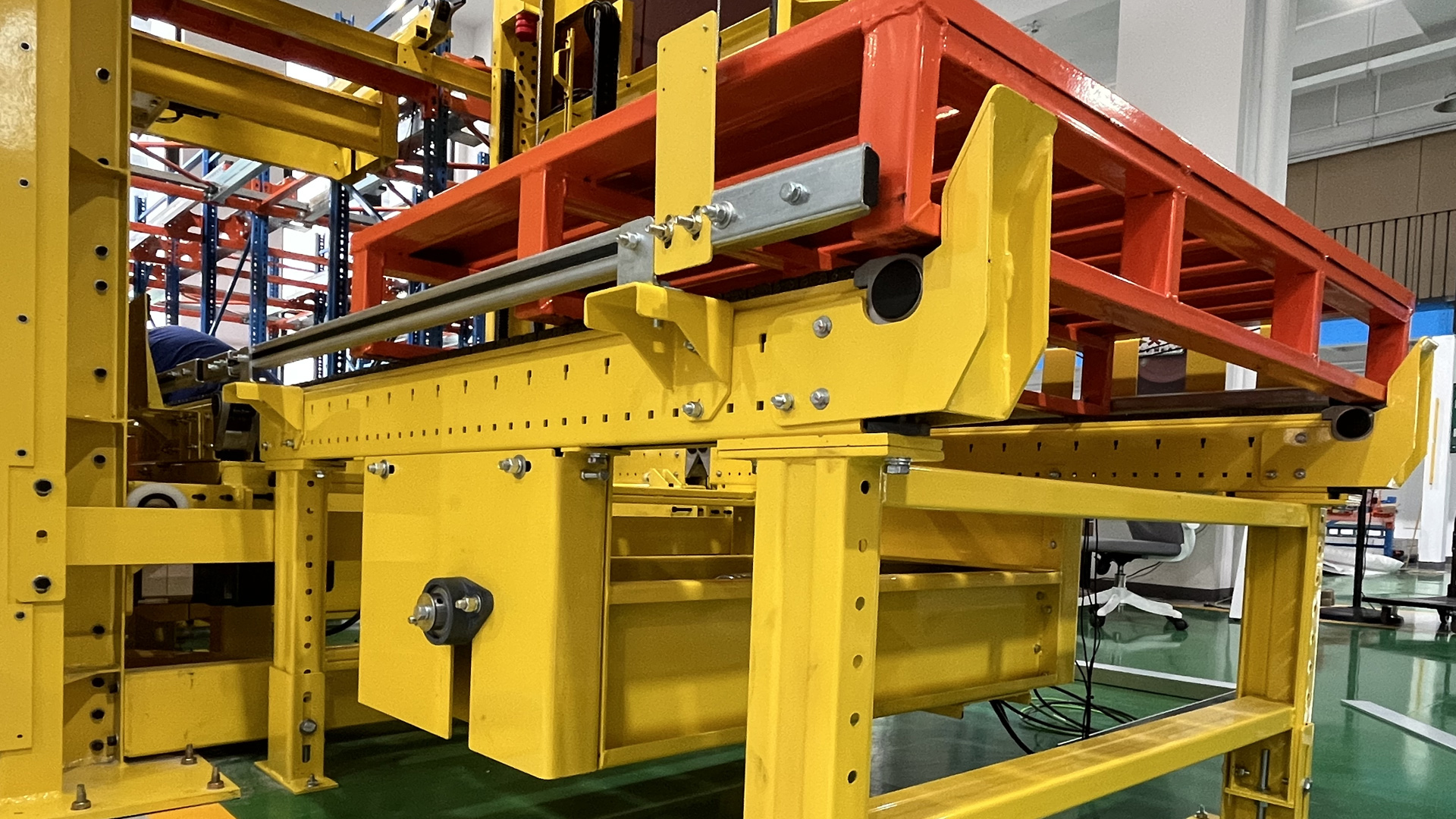

- Material Handling: Chain conveyors are capable of handling a wide range of materials, including packages, cartons, pallets, and even bulk materials.

- Flexibility: They can be configured to have straight and curved portions, allowing for efficient layout and utilization of warehouse space.

- Durability: Constructed from robust materials, chain conveyors are designed to withstand the rigors of continuous use in a warehouse environment.

- Control Systems: Often equipped with advanced control systems that allow for precise speed regulation, stop-and-go operation, and integration with other warehouse automation systems.

Advantages

- Efficiency: Chain conveyors significantly increase the speed and efficiency of material handling in warehouses.

- Reliability: With proper maintenance, they offer a reliable and consistent performance over time.

- Customization: They can be customized to fit specific warehouse needs, including different conveyor lengths, widths, and speeds.

Applications

- Receiving and Shipping: Used to transport incoming and outgoing materials quickly and efficiently.

- Storage and Retrieval: Facilitate the movement of materials within the warehouse, making it easier for workers to access and retrieve stored items.

- Sorting and Packaging: Assist in sorting and packaging materials for distribution or shipment.

In conclusion, chain conveyors are an essential piece of equipment in modern warehouses, providing a reliable, efficient, and customizable solution for material handling. Their ability to transport a wide range of materials over long distances and in various configurations makes them a valuable asset for any warehouse operation.