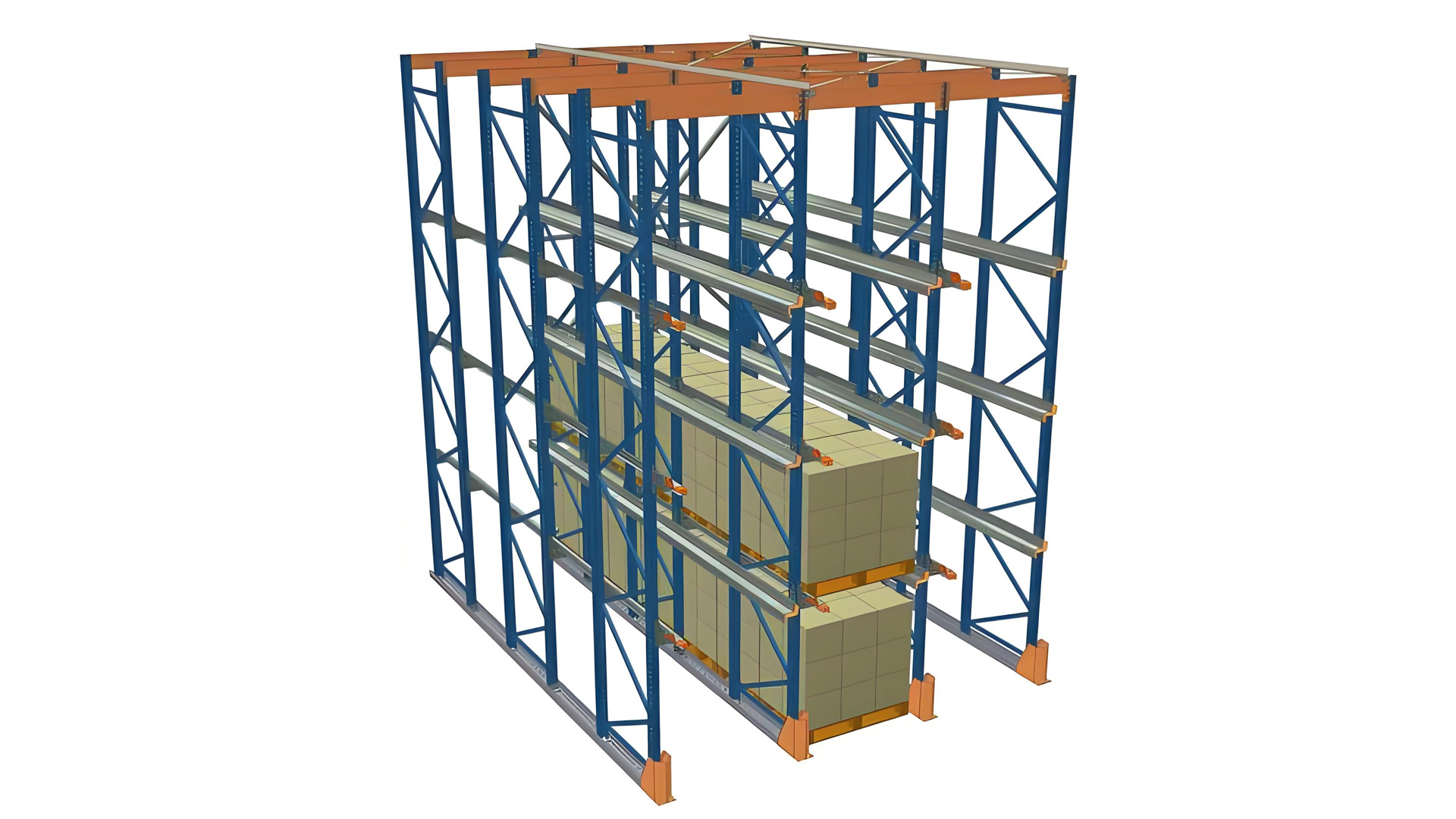

Introduction to drive-in racks

Drive-in racks, also known as through racks or gallery racks, are a shelving system designed for high-density storage. It adopts high-density tunnel three-dimensional storage structure, and works with forklift trucks to drive goods directly into the roadway for storage and use. On each roadway of the drive-in shelf, the forklift drives the pallet goods directly into the direction of depth, and stores them in the order of the upper and lower three-dimensional rankings, forming the overall storage effect.

Usage scenario

Cold chain logistics industry: For cold stores that need to maintain a low temperature environment, drive-in racks can maximize storage capacity and reduce the surface area of cold air loss, thereby reducing energy consumption and operating costs.

Food and beverage industry: products involving a large number of standardized packaging, such as bottled beverages, canned food, etc., these goods are large and uniform in size, suitable for intensive storage by drive-in racks.

Wholesale and retail: Wholesalers and large retailers can greatly improve the storage capacity of warehouses in the pre-holiday promotion phase, ensuring that there is enough inventory to meet the large number of shipments in the short term.

Automotive parts industry: able to carry heavy cargo, through optimized layout, achieve effective management of low-turnover parts, reduce warehouse footprint, improve overall operational efficiency.

Advantage

Efficient use of space: Because there is no need to set up a separate forklift channel for each row of racks, but all forklifts share one or a few channels, so the non-storage area is greatly reduced, and the warehouse utilization rate can be increased by more than 50% compared to traditional racks.

Storage capacity increase: each channel can be set on both sides of the multi-layer cargo, to adapt to different sizes of goods, by adjusting the height of the beam, can store a large number of the same type of goods, especially suitable for storing large quantities, single varieties of products.

Cost savings: Because it can greatly increase the storage capacity per unit area, thereby reducing the cost per unit of freight space, it is an obvious advantage for large-scale warehousing operations in pursuit of economy.

Simple structure and low cost: under normal circumstances, the cost of each pallet storage location is 200 to 350 yuan.

Good flexibility: it can be customized according to the actual needs of customers.

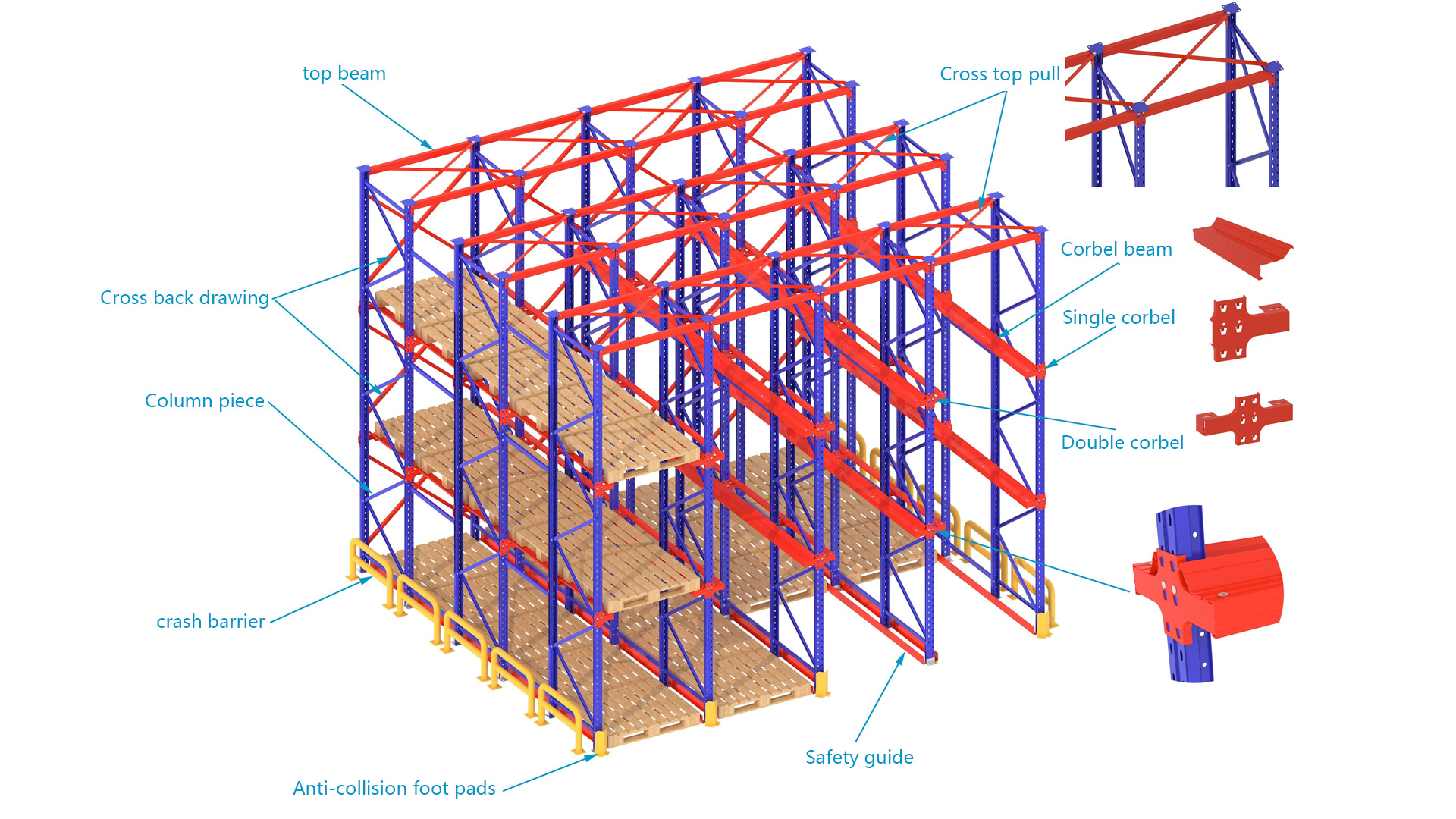

High safety: The shelf is welded with high-strength cold-rolled steel combination, high strength and not easy to deformation.

Good aesthetics: the appearance of the racks is neat and generous, and coordinated with the warehouse environment.

Shortcoming

There are defects in stability: The stability of the drive-in shelf system is the weakest of all types of racks, and special attention is needed in the design. The shelf height should not be too high, generally within 10 meters is appropriate, while the system also needs to add a tension device.

High operating risk: the forklift needs to be operated inside the shelf, and the operator's vision inside the shelf is not open enough, and the light is insufficient, which increases the risk of operation.

Limited to the first-in-first-out principle: The drive-in shelf has higher requirements for first-in-first-out, and it is not suitable for small batches and many varieties of goods.

There are limitations in space utilization: space above 6 meters cannot be operated, and space utilization is insufficient.

In summary, drive-in racks have a wide range of applications in many industries, and their advantages of efficient use of space, increased storage capacity and cost savings make them an effective tool to improve storage efficiency and reduce costs. However, it is also necessary to pay attention to its stability and operational risks when using it.